| |

|

- We partner with OEM process tool manufacturers to provide full turn-key, and custom, automation handling solutions.

- We customize the automated solutions to meet end customer specifications, and allow them to be integrated into end users production environments.

- We have extensive experience with different wafer types, different OEM process tools, and different factory integration requirements.

- CHAD can supply standard wafer handling solutions to meet your non-standard wafer handling requirements.

|

|

|

| |

Capabilities

- Wafer Handlers for 50mm to 450mm Wafers

- Wafer Thickness Down to 75µ

- Experienced in Handling Non-Standard Wafers, Including: Film Frame, Glass, Perforated, Reticle, Substrate, Thin, Trenched and Warped

- Support for All Packaging Types, Including FOUP-POD, SMIF-POD, Open Cassette, Coin Stack and Film Frame

- Cleanliness Levels Down to ISO Class-2

- CE, S2, and S8 Compliant

|

| WaferMate200 |

|

- Formed sheet metal construction

- Low cost

- Small footprint

- For 50mm To 200mm Wafers In Open Cassettes

- Cleanliness Levels Down To ISO Class-4

- CE, S2, And S8 Compliant

|

|

|

| WaferMate300 |

|

- Formed sheet metal construction

- Low cost

- Single FOUP width, or multiple FOUP width

- Small footprint (22” wide)

- For 200mm to 450mm wafers in BOLTS compliant packaging:

- Cleanliness Levels Down to ISO Class-2

- CE, S2, and S8 Compliant

|

|

| |

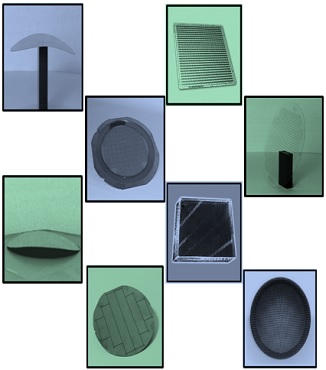

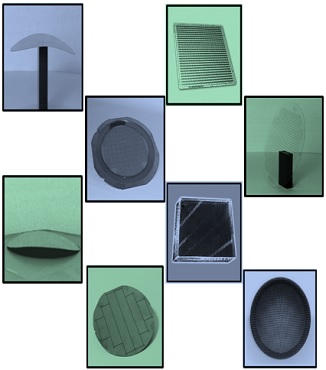

Non-Standard Wafers

We can handle any kind of wafer:

- Thin (< 75um thick)

- Warped (up to 10mm)

- Trenched

- Glass

- Substrate

- Reticle

- Film Frame

- Perforated

- Bumped

|

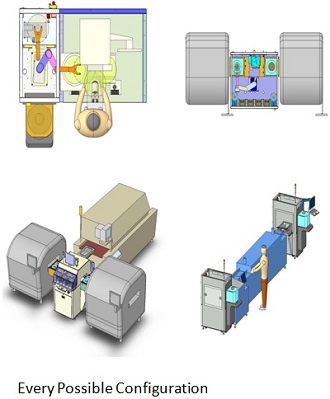

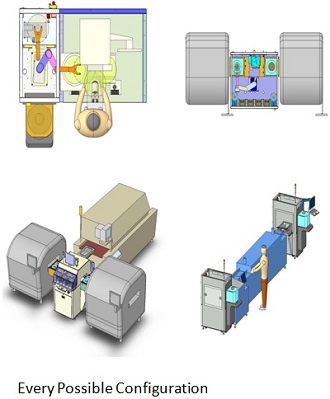

| Line Configurations

Different configurations include:

- Supporting One Tool

- Supporting Two Tools (Either Sequentially Of Independently)

- Supporting Three Tools

- Supporting Inline Process Equipment (Loading And Unloading)

|

|

|

|

|