| |

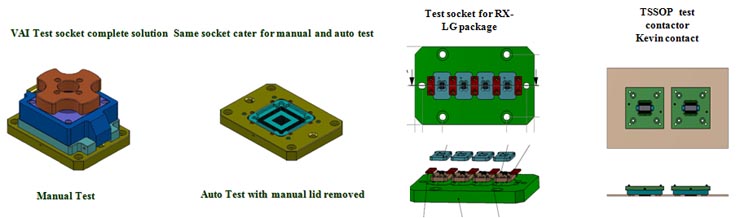

| VAI Test Contactor |

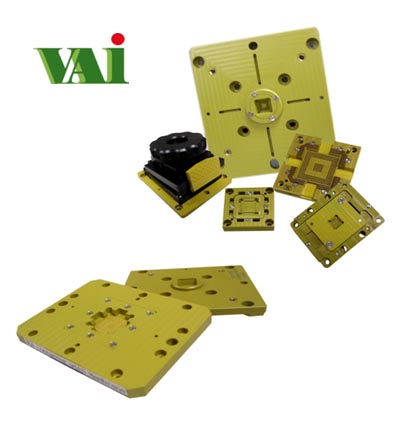

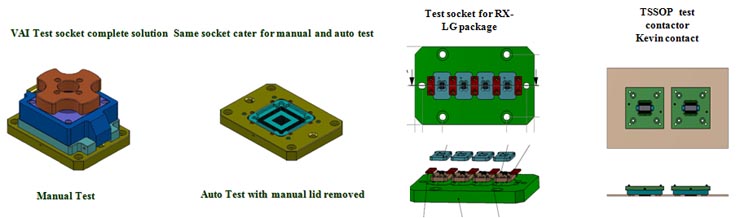

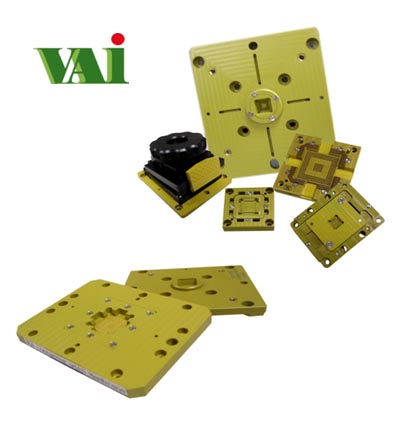

VA offers highly reliable and low insertion force Test Contactors which utilize a variety of miniature double ended contact pins. Also offers a wide range of replaceable contact pin to meet your high frequency testing requirements. These are excellent for production testing of semiconductor devices. VA is committed to provide a comprehensive and well designed test contactor solution depending on client's requirements.

- Using double ended spring loaded contacts

- Offer different tip style for various applications

- Minimized solder migration

- Consistent contact resistance & spring force throughout life cycle

- Customized to your unique need and requirement

- Short lead time and competitive price

|

|

FEATURES

- Designed to fit Module.

- Allows for easy insertion and removal of module for upgrade, replacement and repair.

- Eliminates damage of valuable PCB's.

- Perfect for high volume production applications and prototypes.

- Good compliance between the device & contacts.

- Uses a special surface mounting to your printed circuit board.

- Special prototyping adapters designed on request allowing socket to be plugged into standard prototyping boards.

- The Material socket body allows for device alignment with high wear resistance & low thermal coefficient of thermal expansion.

- The socket body utilize coarse & fine alignment with tapered guides to ensure ease of entry.

APPLICATIONS

- Hand-Test.

- Prototyping.

- Good electrical performance.

- Qualification.

- Development.

- Device Stability.

- Mass Production.

- Future Upgrades.

- Allocation Issues.

|

|

| |

|

| |

|

| Contact Pin |

FEATURES

Miniature double ended spring loaded contact pin.

Minimize coplanarity of the balls on DUT.

Pitch:

1.27 mm; 1.00 mm; 0.80 mm; 0.50 mm; 0.40 mm; 0.3 0mm

Short contact / short pin length.

Minimize capacitance, inductance and contact resistance.

Good electrical performance.

Best for high frequency / high speed testing i.e. RF-Devices.

Special Spring Design : “Barrel shape – ensure consistent contact.

Long life span : -> 300k in general, >500k insertions – BGA package at ambient temp.

Solder migration – minimal -> low Maintenance.

Wide range of pin sizes: Standard / custom made.

|

|

|

|

|

Burn-In Socket |

|

|

Offering its customers state-of-the–art Burn-in Sockets for more than 30 years. We continues to be committed to meeting its customers’ needs in quality, service and support.

- Offers a full line of fine pitch BGA test and burn-in sockets and the latest selection of QFN sockets in the industry. The fine pitch BGA sockets are available in 0.50mm, 0.65mm, 0.75mm and 0.80mm pitch configurations. QFN sockets are available in lidded and open top styles in over 80 different JEDEC footprints. Both BGA and QFN sockets are now available with thermal management.

- Has the new range of socket using Ultra Spring contacts for Dual-row QFN and .5mm – 1.27mm pitch LGA sockets. This Ultra Spring contact, originally created for high-speed testing that can handle up to 25GHz with a –1dB loss has been modified by us for burn-in testing to offer the smallest pure vertical contact ever made.

- Also offers sockets for LCC, PLCC, SOP, TQFP, TSOP and BGA devices of 1.00mm, 1.27mm and 1.5mm pitch.

|

|

|